1. We need to start first and make templates in the process of production and processing. The template needs to be produced in strict accordance with the requirements of customers

2. Extrusion deformation process of guardrail plate: guardrail plate is divided into two wave guardrail plate, three wave guardrail plate and two wave three wave transition plate. Select different production equipment for processing

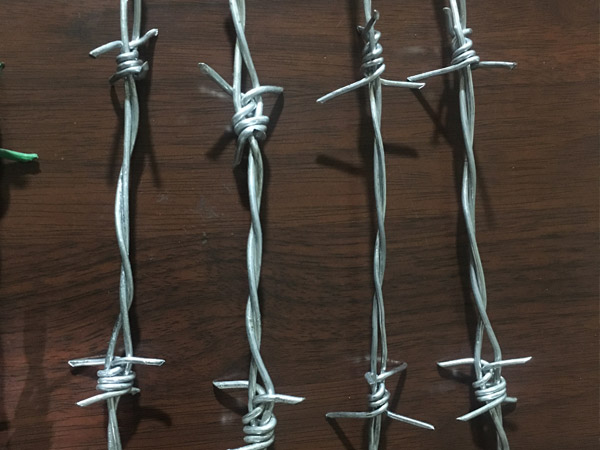

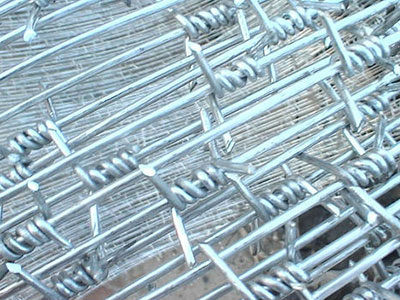

3. Galvanized anti-corrosion treatment of guardrail plate: guardrail plate must have good effect. The extruded guardrail plate needs to be galvanized in the high-temperature galvanizing furnace. The temperature of galvanizing furnace shall not be too high or too low. This needs to be strictly controlled, otherwise it will directly affect the effect.

4. Spray plastic treatment of guardrail board: spray plastic treatment is also very strict. Some manufacturers produce uneven spray plastic guardrail plate, spray plastic effect is poor. This is because the spray equipment of the guardrail board is not good. The spray equipment is all assembly line operation, and the good spray equipment is very even. Shenzhen Hongli facilities Co., Ltd. specializes in the production of wave guardrail, high-speed guardrail, guardrail column, flange column and other high-speed traffic facilities. General specification for corrugated breast board the surface of tungsten Board shall be hot-dip galvanized or hot-dip galvanized and spray plastic anti-corrosion treatment, the more common one is hot-dip galvanized. W plate double wave fence plate: 4320 * 310 * 85 * 3mm / 4mm; W plate three wave fence plate: 4320 * 506 * 85 * 3mm / 4mm; W plate (double wave fence plate) can be divided into 9 hole plate, 10 hole plate, 9 hole and 10 hole reinforcing plate to meet different installation requirements.

Lable: