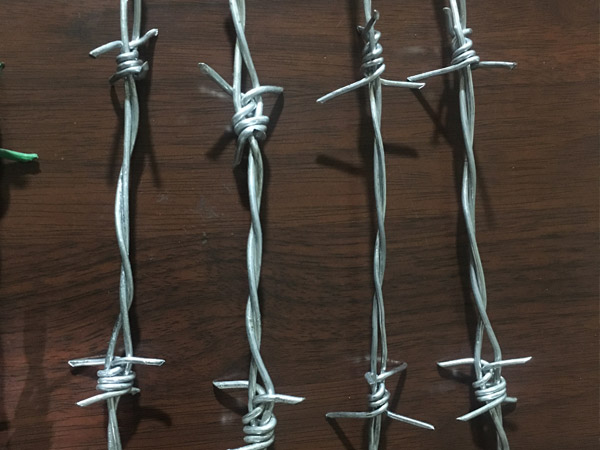

Annealed wire

Annealed wire is a kind of soft iron wire product made of low carbon steel by cold drawing, heating, constant temperature, heat preservation and other processes. Iron wire has different components according to different purposes. It contains iron, cobalt, nickel, copper, carbon, zinc and other elements. The hot metal billet is rolled into 6.5mm thick steel bar, i.e. wire rod, which is then put into the wire drawing device to draw lines of different diameters, and the hole diameter of the wire drawing plate is gradually reduced, and various specifications of wire are made by processing technologies such as cooling, annealing, coating, etc.

Introduction to annealed wire

The production of iron wire developed earlier because of its simple technology and wide application. Iron wire or steel wire (the corresponding enterprise is the "wire mesh enterprise") is a cold-working product of steel wire, and the materials used are generally high-quality low-carbon steel or stainless steel. Generally, the iron ingot (ingot) for making iron wire (steel wire) can be produced only through several procedures, such as peeling, pickling, washing, saponification, drying, drawing, annealing, cooling, pickling, washing, galvanizing, packaging, etc.

Advantages of annealed wire:

Black iron wire has good elasticity and flexibility. It can control its hardness and softness during annealing. It is made of high-quality iron wire and mainly used as binding wire and wire in construction industry. The wire size mainly includes 5 × 3-38 × 3 (wire diameter 0.17-4.5mm), which is softer, more flexible, more uniform in softness and consistent in color.

Wire drawing and galvanizing are widely used in the production of iron wire and steel wire. In 1976, Guangzhou galvanized iron wire factory first applied the new technology test of electrolytic pickling, high-pressure washing and card electricity drying in China to succeed in the continuous production of wire drawing line, which changed the drawing process from intermittent production to continuous production, weakened the labor intensity and reduced the metal consumption. At that time, the domestic iron wire factory has been able to produce steel wire rope, spoke steel wire, umbrella bone steel wire, spring steel wire, bicycle saddle spring steel wire and other products. In the 1980s, the hot-dip low-carbon steel wire for stapling, the steel wire for fan net cover, the steel wire for carbon structure, the steel wire for bed surface, etc. also came out one after another.

Purpose of annealed wire:

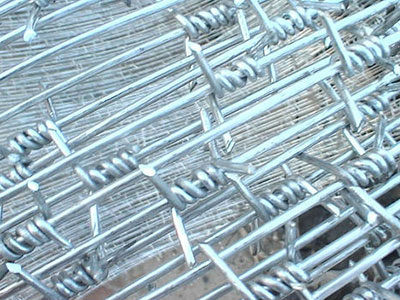

The wire mesh can be woven before plating, plating before weaving, etc. the treated wire mesh or wire mesh has good anti-corrosion and anti-oxidation characteristics, which can be used for reinforcement, protection and heat preservation of construction, petroleum, chemical industry, breeding, garden protection, food processing and other industries.

For example, the welded wire mesh widely used in industry, agriculture, breeding, construction, transportation, mining and other fields is made of high-quality low-carbon iron wire, and then through surface passivation and plasticization treatment such as cold plating (electroplating), hot plating, PVC coating, etc., the metal mesh mesh produced is flat, uniform mesh, solid solder joints, and has the characteristics of stability, corrosion prevention and good corrosion resistance. The stainless steel electric welding net is made of high-quality stainless steel wire by row welding, such as machine protective cover, animal and animal fence, flower and wood fence, window fence, passage fence, poultry cage and food basket, paper basket and decorative articles in family office, etc., which are more acid resistant, alkali resistant, welded firmly and beautiful.

Label: Annealed wire、 Annealed wire厂家、 Annealed wire价格、